Scientists of South Ural State University have solved the problem of reducing electricity and gas costs in Russian homes by 10%. Enormous savings can be achieved by reconfiguring the automatic boiler controllers in a specific way. The development is patented and successfully tested in one of the residential complexes of Chelyabinsk (Russia).

Automatic regulators are used for regulating the temperature of the coolant in pipes and batteries, depending on the temperature of the external air and require competent settings in accordance with the characteristics of each residential complex. Most of the setup instructions are general, “abstract” in nature, which leads to a simplified control mode, in which the coolant temperature fluctuates in relation to the required by 5‒10 ° С. This increases energy and gas consumption in residential buildings.

SUSU scientists have patented a unique way to adjust the optimal ergonomic mode of operation of autoregulators (patent No. 166606) and implemented it in one of the modern residential complexes in Chelyabinsk.

“Many years of experience working with precise regulatory systems supported us to discover innovative technology. We introduced such regulation in a big residential complex in the city of Chelyabinsk, for 4 years we have been monitoring the consumption of resources, mainly gas. After adjusting the parameters of the regulator, the flow rate decreased by 10%. We developed our own methodology and achieved the best efficiency of the regulators we work with,” says Vladimir Kodkin, the author of the patent, doctor of technical sciences, professor of the automated electric drive department of the SUSU Polytechnic Institute.

Oscillations in the temperature control system of the coolant, which is formed with the "factory" parameters of the regulators, significantly impair the operation of control systems and heating systems. In this case, the amplitude of the temperature fluctuation is up to 10 ° С, which leads to gas overconsumption of 10–15%. As a result of employing their own methodology for setting regulators, scientists were able to eliminate temperature fluctuations and reduce its amplitude from 10 ° C to 1 ° C. Today, electricity and gas consumption is reduced by 10%, but in the future this figure maybe 20–25%. Moreover, the new settings of the regulators will not have a negative impact on the quality of heating of residential buildings. The solution proposed by the scientific team does not require enormous financial costs and the installation of experimental specific equipment.

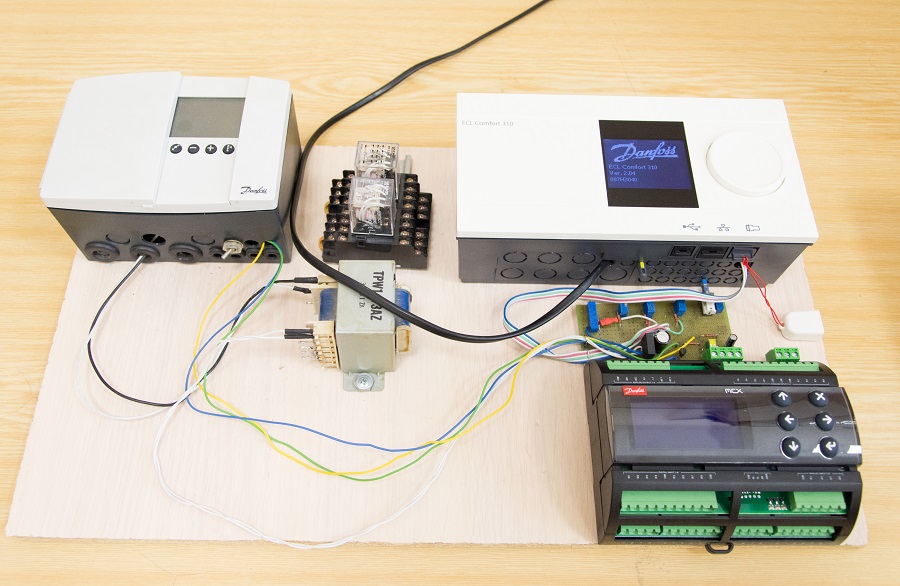

The university’s industrial partner, which provided regulators for testing, was the largest Russian manufacturer of energy-saving equipment - Danfoss. In 2019, a framework agreement on cooperation was agreed between the enterprise and SUSU. Currently, proposals are being prepared for joint research in the field of optimization of heating systems.