Gate valves of various designs and sizes are widely used as shut-off valves for main oil pipelines and gas pipelines, as well as in the systems of fire fighting and water supply. The researchers of South Ural State University are working on improving reliability and operation efficiency of such devices according to the task by one of the major manufacturers of pipeline assemblies in Russia – KONAR Company.

Simple and Convenient Mainline Valves

The research by the SUSU Polytechnic Institute Master’s student Andrey Shlishevsky is devoted to the influence of casting defects on the strength of large-size casting structures with regard to the body of the main pipeline gate valve weighing several tonnes. The academic advisor is Candidate of Sciences (Engineering), Associate Professor of the Department of Engineering Mechanics Vadim Poroshin.

One of the main advantages of gate valves is low hydraulic resistance, that is why they are widely used as part of main pipelines, where working medium flow rate may be quite high. Gate valves are characterized with simple design, small face-to-face dimension, comparatively low price, and the possibility of operation in very different climates for transportation of heterogeneous mediums.

Problems with Gate Valves Operation

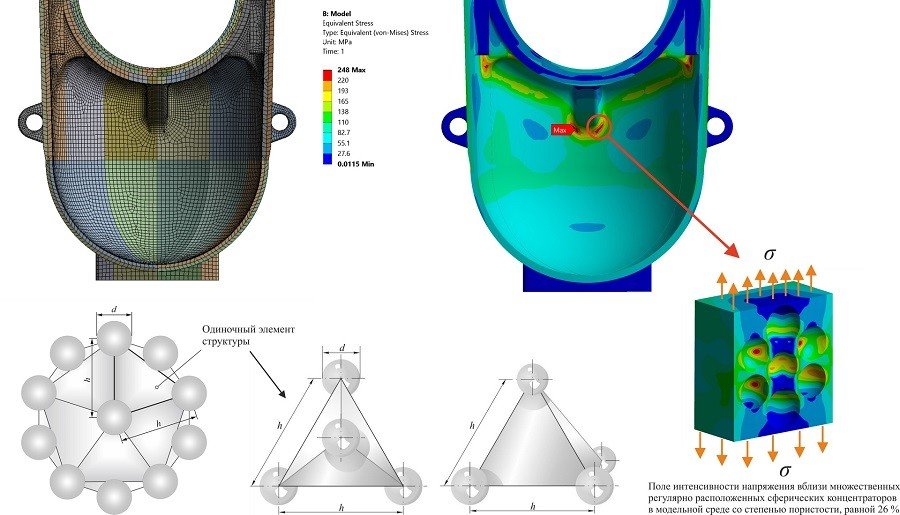

“Often in the process of casting large capacity workpieces, and in particular of gate valve bodies, internal defects occur – gas bubbles, non-metallic impurities, and other – which affect the design’s strength. Unfortunately, in the currently available scientific and technical literature there is practically no information on models of inelastic deformation and destruction of porous structure bodies in case of repeated and variable loading – and these are typical operation conditions for mechanical engineering goods. And ignoring material defects will result, as you may easily guess, in inaccurate assessment of strength. Our research aims at developing mathematical models of deformation and strength properties of metal materials with porous defects both at one-time and cyclic loading,” explains Andrey Shlishevsky.

Fatigue, the main mechanism of an object’s losing its working efficiency in case of repeated and variable loading, is quite a difficult phenomenon to be described mathematically. This is related to the fact that different mechanisms of damageability and destruction exist, which depend on the nature of external impact; moreover, the situation may be exacerbated by other unfavourable factors (high temperature, strain ageing of metal, corrosion, and other).

“The limit state of a design is reached as a result of gradual accumulation of damages by the material which is accompanied by changes in both its deformation and strength properties, and what leads to occurrence of first micro- and then macro-fissures. Thus, the life of shut-off valves is mainly determined by their resistance to fatigue damage,” continues SUSU Master’s student.

Mathematical Model of Mainline Valve

Unique Method of Computing of Yielding Porous Mediums

For designs manufactured from brittle materials, such as ceramics for instance, usually a forward calculation of strain-deformation state of material with multiple chaotically distributed pores is used. The procedure of forecasting deformation and strength properties of such model medium is corrected after correlation with the experiment results. And though brittle materials have relatively simple patterns of deformation and destruction, significant computing powers are used to fulfill this approach, often including supercomputers.

“The idea of our project is development of a method of building a model of continuous homogeneous medium, which in its deformation and strength properties would be equivalent to material with defects. By now, based on our experiments, a collection of deformation-in-case-of-loading diagrams have been built, accounting for materials of various porosity. These diagrams will be used for further assessment of the design’s deformation in general,” shares Andrey Shlishevsky.

The computation research studies are being performed with the help of ANSYS software complex. The work seriously focuses on building a correct model of the most loaded zone of the gate vale body, what will allow to claim the accuracy of the results obtained through its use.

Results Important for the Chelyabinsk Industry

The student of South Ural State University further on plans on developing an algorithm and assessing durability of design with consideration to porosity of an actual material in case of loading on a certain section of one of the pipelines; and he also plans to successfully defend his Master’s thesis. Once Andrey Shlishevsky graduates, he will have a chance to test his theoretical calculations on practice, as his research was initiated by KONAR production enterprise dealing with development, engineering and complex support for gas, oil and petrochemical industry, and which is interested in successful results of the research.

The results of the performed scientific work will be presented at the 12th International Conference on Mechanics, Resource and Diagnostics of Materials and Structures in Yekaterinburg, as well as will be published as an article in top-ranking journal Materials Today: Proceedings, indexed in Scopus (Q1) and Web of Science scientometrical databases.