Each epoch has an impact on urban architecture. Changes affect not only external appearance of buildings but also their component elements. The most topical today is the question about producing innovative building materials complying with characteristics of reliability, environmental compatibility, speed and simplicity of their manufacture.

Clean construction within a short time

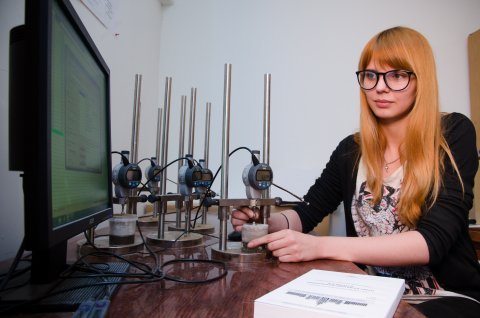

Creation of such eco-materials – high-quality and safe for the environment – is exactly what scientists of South Ural State University are working on. “Development of a technology for producing building structures out of magnesium concrete armored with composite reinforcement” is the title of the winning project of the Scientific Potential contest held within the frameworks of the program for increasing competitiveness of Russian universities. The main goal of the project is to create a new building material with enhanced qualitative characteristics. Galina Averina, the author of the research and a postgraduate student of the SUSU Institute of Architecture and Construction, told about properties of magnesium concrete armored with composite carbon-fiber reinforcement.

“We are developing a material in which modified magnesium wastes of refractory and mining industries are used as a binder, instead of Portland cement, the binder which is more popular today. As the main advantage of using the new type of binder we consider its possibility to quickly acquire high strength. Production cycle on the basis of magnesium binders takes only one day whereas Portland cement concrete acquires its handling strength after two days at best. Another advantage is in the fact that magnesium concrete acquires strength under normal conditions and doesn’t require special steam treatment. Such treatment, as we know, increases self-cost of finished product in not less than 30%. If we are talking about producing high-strength concrete, with the use of magnesium binder it will become possible to acquire strength values from 60 to 80 MPa without special expensive additives. Therefore it is easy to calculate that producing magnesium heavy concrete and structures on its basis will be cheaper.”

Clean product for clean atmosphere

Production of magnesium binder implicates for cryo annealing. In other words, it is more eco-friendly due to a lesser emission of carbon dioxide to the atmosphere. Developing a technique for manufacturing armored products on the basis of magnesium binders will allow significantly extending the sphere of their use in construction, which in turn will accelerate the process of recycling tailings of magnesium production wastes. As a result, the developed material, aside from high qualitative characteristics, will possess high environmental efficiency.

.jpg)

Photo: Concrete sample with carbon-fiber reinforcement

“Magnesium concrete is practically similar to ordinary concrete,” notes Galina Averina. “We are researching the possibility of its reinforcement. Reinforcement is a technique to increase bearing capability of a structure by material which possesses enhanced strength properties compared to the product’s general material. For example, concrete possesses high strength characteristics during compressive loads which become very insufficient if it comes to transversal loads. In other words, if a concrete plate is lying on two support poles it can break even under its own weight. Though if it lies on a flat surface, it can be loaded anyhow within the design strength. Steel reinforcement is injected in the body of concrete so that a plate could easily resist transversal loads. Speaking about magnesium binders, it is necessary to note that specificity of composition of the material’s binding system excludes the use of metal reinforcement. Therefore we are researching the possibility of the use of carbon-fiber reinforcement, which by its qualitative characteristics is no worse than steel reinforcement, in magnesium concrete.”

.jpg)

Photo: Tested cube-shaped samples of trial composition of additives-free magnesium concrete

“It doesn’t burn in fire”: properties of magnesium concrete

Nowadays there are three articles concerning this topic published in scientific journals indexed in Scopus database (“Institutes of Physics: Conference Proceedings”, “MATEC Web of Conferences”, “IOP Conference Series: Materials Science and Engineering”). At the moment, the team of scientists from the Institute of Architecture and Construction performs development of the optimal composition of heavy concrete with the least expenses for its more costly component – the binder. The next step will be research of the principles of interaction of carbon-fiber reinforcement with magnesium binder. It is also planned to determine reinforcement’s resistibility in a medium of saturated salts. This research will help to answer the question about how the reinforcement will ‘feel’ while being placed in a body of magnesium stone.

Another advantage of this building material, aside from the abovementioned, is the fact that its manufacturing requires less labor and time consumption. On top of everything else, magnesium concrete possesses high wear resistance and resistance to exposure of various organic mediums such as oil, petrol, oil products, etc. The material is bioresistant (which means it does not exposed to the growth of mold fungus) and water-reistant which allows using it when constructing hydraulic engineering structures. Sparklessness of magnesium concrete eliminates occurrence of fire or explosions in industrial buildings belonging to the class of increased hazard buildings. These properties of the material prove its perspective for the construction market and its wide range of applicability.