Scientists from South Ural State University have become the first in Russia to create a fundamentally new composite material capable, under the influence of ordinary sunlight, to convert inexpensive organic compounds into commercially valuable products. The results have been published in the Catalysis Letters journal .

The technology will make the production of pharmaceutical components and polymers safer, single-step, and less dependent on imports.

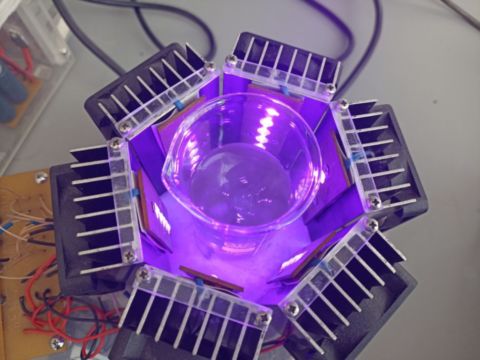

Researchers have developed an innovative photocatalyst: a substance that accelerates chemical reactions when exposed to light. Unlike existing analogues used, for example, to purify air or water, the new development is designed for the selective synthesis of organic compounds.

"In our experiments, we obtained benzaldehyde from benzyl alcohol. Benzaldehyde is 10 times more expensive and is synthesized industrially using chlorine," commented Mikhail Golovin, Senior Research Fellow at the SUSU Nanotechnology Research Centre. "Chlorine is a highly toxic gas that is difficult to store. The world is trying to discontinue using it, so scientists need to find new methods for producing the necessary substances. Benzaldehyde is widely used in the pharmaceutical and polymer industries."

The composite photocatalyst developed at SUSU has the potential to be used to produce any organic substances. The key advantage of the technology is its "green" nature. The process takes place in a single step, at room temperature and atmospheric pressure, and uses sunlight as the primary energy source. This eliminates the need for traditional methods, which often require high temperatures, pressure, and toxic reagents.

The development's novelty lies in the catalyst's composite structure, which combines an organic polymer (polytriazine amide) and iron oxide. According to the scientists, the synergy between the components produces an effect superior to the simple sum of their properties. All the starting materials for creating the catalyst are readily available in Russia and are inexpensive. The development by the Chelyabinsk researchers offers not just a new catalyst, but an alternative and more environmentally friendly approach for the domestic chemical industry.

The technology can be applied in two key sectors: pharmaceutics (for the production of medications substances and components, such as capsules) and chemical industry (for the synthesis of plasticizers and other substances used in the production of polymeric materials).

This paves the way for import substitution of critical components and simplification of process chains. The method has been tested in laboratory conditions. The scientists note that the technology is scalable, and its industrial implementation will require equipment adaptation.

The research is consistent with the goals and objectives of the "New Materials and Chemistry" national project.